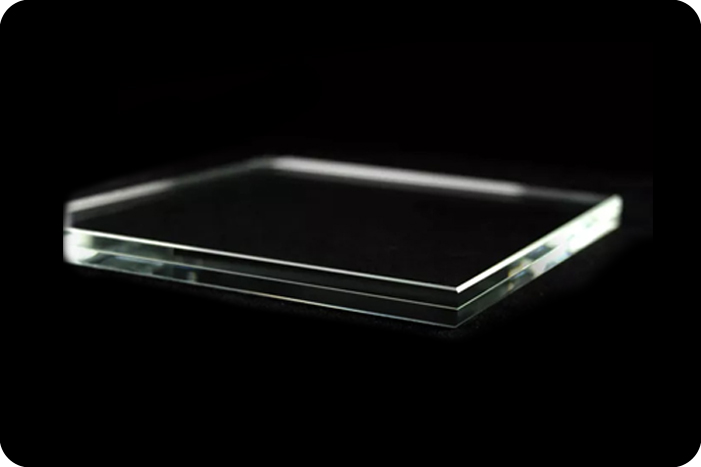

Low reflective laminated glass is more than just a tool for enhancing visual appeal and light transmission in buildings or exhibitions—it's a marvel of engineering designed to offer exceptional safety, durability, and protection. One of its standout features lies in its laminated structure, which plays a critical role in providing robust impact resistance and safety, ensuring that this glass remains a trusted choice for high-security applications. But how exactly does this laminated structure contribute to its remarkable safety features? Let’s dive into the science behind it.

At the core of laminated glass is a unique construction involving multiple layers of glass bonded together by a durable interlayer, typically made of materials like PVB (polyvinyl butyral) or EVA (ethylene-vinyl acetate). This interlayer serves as the backbone of the glass’s strength, offering a layer of resilience that absorbs and distributes impact forces evenly across the surface. Unlike regular glass, which can shatter into sharp, dangerous fragments upon impact, laminated glass remains intact even when broken. The interlayer holds the shattered pieces together, preventing them from scattering and creating a potential hazard. This feature alone makes laminated glass a preferred choice for environments where safety is paramount, such as in windows, skylights, and museum displays, where a broken pane can pose a serious risk to people or priceless artifacts.

But the safety benefits of laminated glass don't end with its ability to prevent dangerous shards. The interlayer also enhances the glass’s resistance to forced entry, which makes it a common material in security applications. Whether it’s a window that needs to withstand the impact of a thief's tool or glass in a high-traffic public space, the laminated structure makes it far more challenging to penetrate. It effectively delays break-in attempts and increases the time needed to break through, offering crucial protection for both property and individuals. This makes low reflective laminated glass an excellent option for high-risk areas such as banks, museums, and even in the automotive industry for windshields that need to stand up to impacts.

One of the lesser-discussed but equally important benefits of the laminated structure is its capacity to absorb sound and vibrations. The interlayer not only keeps the glass from breaking but also acts as a sound-dampening barrier, making laminated glass an excellent choice for applications where noise reduction is necessary. This can be especially valuable in urban settings or in buildings near busy highways, where reducing noise pollution can create a more comfortable environment.

Additionally, its ability to block ultraviolet (UV) radiation adds another layer of protection, safeguarding not only the building’s occupants but also any sensitive materials, such as artwork or historical documents, that may be exposed to sunlight. The combination of these benefits, from safety to UV protection, underscores why low reflective laminated glass is often the material of choice in projects that prioritize both durability and preservation.

While the optical qualities of low reflective laminated glass make it an attractive option for those seeking minimal glare and maximum light transmission, the real appeal lies in how its laminated structure enhances its overall safety profile. Whether it’s the glass’s ability to remain intact in the event of breakage, its resistance to forced entry, or its noise-dampening capabilities, the laminated design ensures that it provides far more than just a pretty facade. In fact, it’s this very structure that transforms simple glass into a multifaceted safety feature that protects both people and valuable possessions. By combining impact resistance with visual clarity and UV protection, low reflective laminated glass offers a comprehensive solution for modern, safety-conscious design.