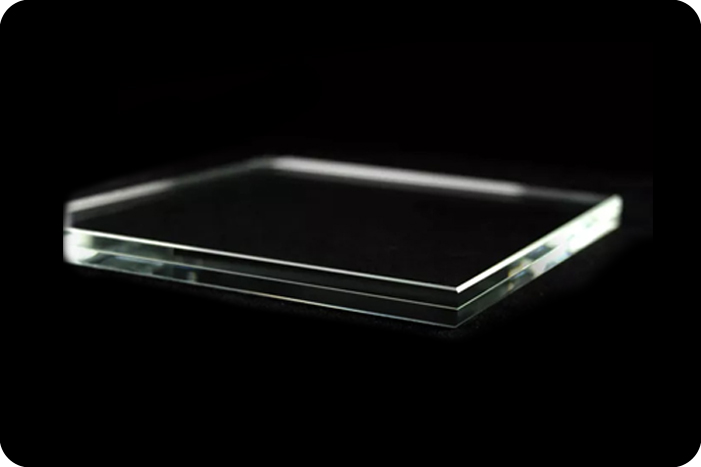

The customization of reflectivity in low reflective laminated glass is a topic of significant interest, especially for projects with specific aesthetic and functional requirements. In many architectural and industrial applications, the ability to tailor the reflectivity of glass can greatly enhance the overall design and performance of a building or product.

The Concept of Customization

Reflectivity in glass is primarily determined by the type and thickness of the coating applied to the glass surface. For low reflective laminated glass, this coating is designed to minimize the amount of light that is reflected back into the environment, thereby allowing more light to pass through while reducing glare. The level of reflectivity can indeed be customized to meet specific project requirements, although this customization comes with certain technical and practical considerations.

Technical Feasibility

From a technical standpoint, the customization of reflectivity involves adjusting the composition and thickness of the anti - reflective coating. These coatings are typically composed of multiple layers of thin films, each with different refractive indices. By altering the number of layers, their thickness, and the materials used, manufacturers can achieve different levels of reflectivity. For example, a coating with fewer layers or a different combination of materials might result in higher reflectivity, while a more complex, multi - layered coating can achieve extremely low reflectivity levels.

Practical Considerations

While it is technically possible to customize reflectivity, there are several practical considerations that need to be taken into account. One of the primary factors is cost. The more complex the coating, the more expensive the production process becomes. This is due to the increased precision required in applying multiple layers and the use of specialized materials. Additionally, the customization process may require specialized equipment and highly skilled technicians, further adding to the cost.

Another consideration is the balance between reflectivity and other performance characteristics. For instance, reducing reflectivity to an extremely low level might have an impact on the glass's UV protection or thermal performance. Therefore, when customizing reflectivity, it is essential to consider the overall performance requirements of the glass in the context of the specific application.

Applications and Benefits

The ability to customize reflectivity offers several benefits for various applications. In architectural projects, low reflective glass can enhance the visual appeal of a building by reducing glare and allowing for clearer views both into and out of the structure. This can be particularly important for buildings with large glass facades, such as museums, art galleries, and high - rise office buildings, where the aesthetic impact of the glass is crucial.

In addition to aesthetics, customizing reflectivity can also improve the functionality of glass in certain environments. For example, in display cases, low reflective glass can enhance the visibility of items by reducing reflections that might otherwise obscure the view. Similarly, in automotive applications, low reflective glass can improve driver visibility and reduce glare, contributing to safer driving conditions.